Forget the Hype! This is how you Should Restore Posterior Implants!

There has been a great marketing movement by most laboratories to tell you that the best option to restore your posterior implants (Any crown that is not in the esthetic zone) is with a stock titanium base and a zirconia or e-max crown on top.

The reason for this movement is quite frankly financial. This type of restoration has the greatest profit margin of any crown type that the laboratory will manufacture. They purchase the stock titanium base cheaply and mill a zirconia or e-max crown on top of it. If you are lucky, they will use a titanium base that is manufactured by the implant manufacturer but mostly likely, a third party generic part will be used that will not only void your implant warranty but also throw the longevity of the whole implant system into question.

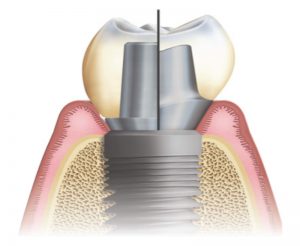

Figure 1: Implant restored with titanium base on left and custom titanium abutment on right.

The implant crown attached to a stock titanium base takes very little manufacturing time and very little technical expertise. The titanium base and the crown are usually cemented and delivered to the dentist. Usually, the cementation protocol attaching the titanium base to the implant crown is not disclosed to the dentist and there is no way to monitor the consistency of the cementation process. Some titanium bases do not require cementation but make no mistake about it, the Achilles heal of every implant system is the attachment to the titanium base.

There are very few studies that have compared the longevity of a titanium base supported implant crown and a crown supported by a custom titanium abutment. However, there should be no doubt that there is only one way to fabricate a posterior crown to insure longevity and retrievability and that is to fabricate a custom titanium abutment and build a zirconia crown on top. If for any reason a crown fractures over a stock titanium base, it will most likely be a catastrophic fracture that will involve ordering of special retrieval tools at significant cost, hours of chair time to retrieve the broken piece out of the implant, a tissue punch or elevating a flap to expose the implant platform to visualize and remove the broken part, and a new implant level impression to fabricate a crown. If however, a crown fractures over a custom titanium abutment, a simple crown-and bridge impression and re-manufacturing of the crown is required. The implant platform is never disturbed and less invasive procedures requiring chair time and patient healing are not required.

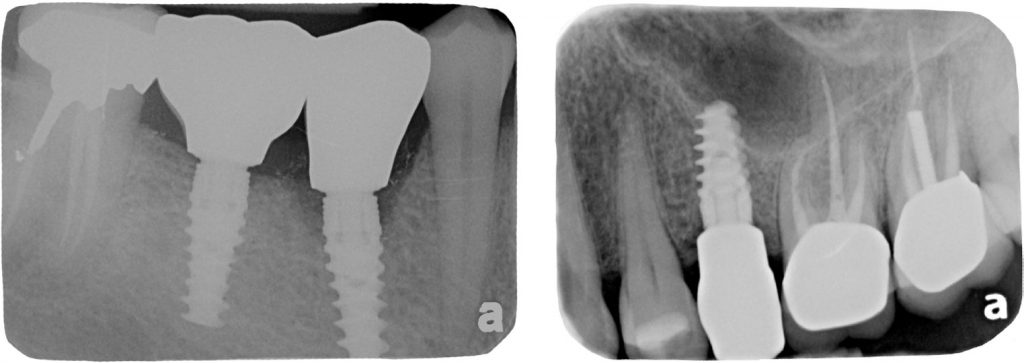

Figure 2: Implants restored with titanium bases or gold abutment showing improper emergence profile and early bone loss.

Some labs who have not kept up with the CAD/CAM manufacturing revolution may be telling you that gold crowns or PFM crowns on top of the implant crown are the “Gold Standard”. That statement is the furthest from the truth. The reality is that gold and PFM crowns over implants prevent a crucial attachment of the abutment to the tissues as they are not biocompatible. Remember that the only biocompatible materials that are currently widely in use in dentistry are: Titanium, Zirconia, and PEEK. Gold and PFM crowns will create long pockets around the implant in the emergence zones that could harbor bacteria and cause peri-implantitis. As far as I am concerned, these types of crowns should be made illegal in the profession of dentistry. You don’t go around placing silver points in endodontic canals, or making dentures out of ivory! You should stop making gold and PFM implant crowns. Before you send hate mail, I use gold and PFM crowns in my practice, but on natural teeth!

- Please fabricate a custom titanium abutment with the margins 0.5 mm subgingivally on the buccal, mesial, and distal and place the lingual margin 1 mm supragingival. Use parts only approved by the implant company.

Reason: If the crown is to be cement retained the cement is easily retrievable. The tissue around the implant will not have a margin close to it. Margins no matter how well sealed will collect debris and bacteria that is not conducive to tissue health. - Make the emergence profile of the custom abutment slightly concave.

Reason: If the crown emergence is made slightly concave, it will allow for more tissue around the implant. - Please gold anodize or use gold nitrite coating.

Reason: If the patient has high esthetic demands, then the gold colour of the custom abutment will give the zirconia crown a warm tone rather than a dull grey feeling. - Fabricate a monolithic low translucency zirconia crown

Reason: This is the strongest type of zirconia crown. It will fracture at close to 1000 mega pascals. The hype these days is to have “translucent Zirconia”. The more translucent zirconia is, the lower its strength. At least for the technology available to us today. - Please make the interproximal contacts broad and have contacts in centric occlusion only. Please have light shimstock contact.

Reason: Broad interproximal contacts minimize lateral forces on implants and prevent food trapping. Light shimstock contact will mean that as the patient bites, the teeth give way slightly and the implant comes into a heavier contact. Note that I am not advocating an open contact as the opposing dentition will eventually erupt uncontrollably.

Dr. Kevin Aminzadeh:

Dr. Kevin Aminzadeh:

Specialist in Prosthodontics

Dr. Aminzadeh pursued his Doctor of Dental Surgery degree from Western University, graduating in 2001. Following a successful decade of practice in Burnaby, he returned to study at the University of Michigan dental school, recognized as a global leader in prosthodontics, where he received his Master of Science in Prosthodontics after an intensive three-year program. His education in the field of implant dentistry was supplemented by a Master Clinician certificate from gIDE institute and Loma Linda University in 2014.

Dr. Aminzadeh is an international speaker and a key opinion leader in the field of implant and microscope enhanced dentistry. In 2015 Dr. Aminzadeh launched Implant Genius, an implant treatment planning service helping oral and maxillofacial surgeons, periodontists, and general dentists. He is an expert in digital record taking, implant treatment planning using implant planning software, implant placement using a surgical guide, and custom prosthodontic restorations.

Implant Genius is the world’s first implant planning company where board certified prosthodontists plan successful dental implant procedures. Dental implants are a complex task — wouldn’t it make sense to have a surgical guide crafted by a board-certified prosthodontist?

Sometimes a wrongly placed dental implant can cause damage that is irreversible. A dental implant performed without planning can lead to teeth that not only look odd but also don’t function properly. Implant Genius was founded to help offer dental implant planning to reduce any implant failure and costly mistakes.

Founded in 2015 with the vision of helping general dentists and specialists place and restore implants flawlessly, our mission is to offer meticulous planning for dental implants, using the best technology possible. This helps increase patient satisfaction and simultaneously grows a dentist’s implant practice by helping deliver highly aesthetic and functional implant restorations that last. We reduce surgical times, surgical and prosthetic implant failures and enhance the predictability of implant restorations.

Our facility is centered on providing a complete digital work flow. We utilize scanners, cone beam CT, Dental Operating Microscope, and a 3D printer. We plan implant placement for almost every implant on the planet, and work with implant companies to provide certified and approved surgical guides.

Dr. Kevin Aminzadeh:

Dr. Kevin Aminzadeh: